Instrumentation Installation

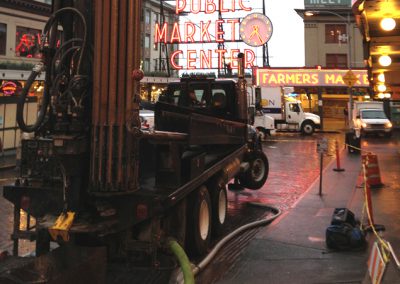

Instrumentation Installation 1, Seattle, WA

Instrumentation Installation 2, Seattle, WA

Instrumentation Installation 3, Seattle, WA

Description and Challenges

We used a larger rig in order to drill a hole as close to perfectly straight vertically as possible from 0-300 feet. The hole was drilled between an existing horizontal tunnel and future horizontal tunnel which are 6 feet apart horizontally and 130 feet apart vertically. The finished hole was 6 inches off vertical at 300 feet deep. (Considered extremely accurate and a real testament to skilled crew members operating the drill rig in tune with the ground conditions.)

Instrumentation Installation 4, Seattle, WA

Description and Challenges

This site, the “launch pit”, is the first stretch for the Alaskan Way Viaduct drilling. It was the most critical and challenging of the drilling sites. The area has the most obstacles in terms of the viaduct drilling and the soil is the most “liquefiable” and unstable. A very experienced drill rig operator is required to drill through the unstable ground and install the instrumentation correctly. This site had a tight schedule so avoiding down-hole complications was critical to complete the drilling and instrumentation installation on-time. In order to qualify to be on this construction site every member of our drilling team completed extensive site specific training. We were pleased to complete our drilling ahead of schedule and injury-free.

Client: Soldata and Hart Crowser

Type of work: Instrumentation installation for the Hwy 99 Alaskan Way Viaduct Tunnel Project at several Seattle locations. These instruments monitor any ground movement caused while the tunnel boring machine is boring under the city.

Equipment: Truck mounted drill rigs, track mounted drill rigs, concrete core machines, and vacuum trailers

Description: Installed over 160 slope inclinometers and multi-point extensometers up to 300 feet deep.

Challenges: Urban drilling, rigorous schedule, and complexity of installations.

See more projects or contact us today to talk with a drilling professional about your drilling project.